“Growth in North America requires increased warehouse capacity in the coming years,” says Anders Geijer, Product Area Manager at H&M, explaining the background for this initiative. Additionally, H&M wanted to improve inventory visibility across channels to increase item availability, improve the customer experience through faster and more accurate order fulfillment, and reduce its reliance on third-party fulfillment partners.

- Fulfill online orders and retail orders from the same warehouse

- Implement goods-to-person robots to automate put-away and picking

- Integrate an AI-driven execution system to increase the customer experience

- Manage overall warehouse operations with SAP EWM

Kiva-style rack storage system

Random mixed storage for online and store fulfillment

Sorting robots for sorting of fully packed shipping units

Combined picking area for omnichannel storage and picking

Advanced high throughput packing workstation

Manual replenishment area with classical RF integration

The objective was to create an integration of AMRs for high-speed order fulfillment with SAP EWM. The integration was done using a Web services approach based on a framework approach for future re-usability. Functionally, we enabled advanced performance optimization strategies in SAP EWM to ensure scalability and throughput, direct carrier integration, and error correction capabilities.

After go-live, performance quickly reached over 1,000 picks per hour enabling completion of over 4,000 customer orders per day. In fact, H&M had planned for at least four weeks of ramp-up and decided that it had reached 95% completion after one week.

The new solution allowed for a complete overhaul of warehouse operations, from put-away and storage to picking and packing. For example, H&M was looking to optimize loading between channels, warehouse layout, and resources. According to Geijer, “it is important to have the capability to manage different channels and to know the priority of all the orders as online channels are not as flexible as store channels in terms of handling customer requests.” Dr. Alexander Bender, Director of Supply Chain Strategy & Execution at Westernacher Consulting, adds: “EWM as the ‘Greybox’ keeps some of the information out of the execution system and lets the execution system focus on optimizing picking and put-away while providing full inventory visibility at any given moment.” In this way, H&M can show customers the available inventory because the warehouse system constantly audits the inventory.

There are a lot of benefits gained from this project, according to Geijer, particularly in two areas: automation and retaining a full inventory picture. H&M now has one inventory view for both channels – retail and e-commerce. Automation also provides a solution to the problem of moving goods across channels; both channels’ inventory is stored in mobile storage units (MSUs). Robots move the MSUs to the induction stations for all inbound processes and to the pick and pack stations for outbound. The system orchestrating the robots and the MSU locations uses AI to ensure the robots perform the right tasks at the right time. MSUs are continuously audited during operations. Since robots bring goods to people, employees no longer work in the aisles which enables a much more secure environment.

picks per hour

customer orders per day

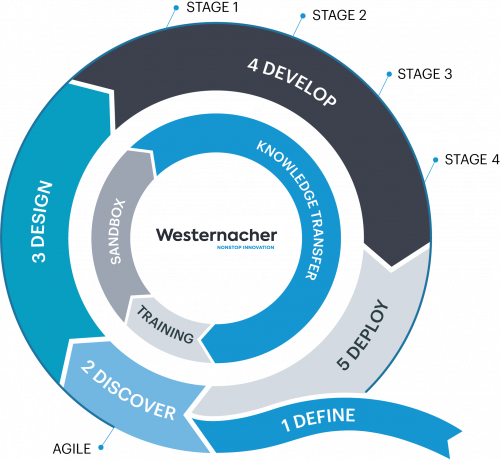

H&M was accustomed to long implementation projects. Setting up a new warehouse would usually take nine months due to the complexity of the existing template. Westernacher’s answer was to propose splitting the solution into two functional go-lives and to apply the Westernacher Q-Methodology.

The purpose of the functional split was to reduce the operational exposure for H&M and the robotics provider. By focusing first on the store business, we enabled the project team (customer IT, warehouse operations, robotics supplier, retail business) to test the new warehouse with its robots using the simpler business processes, a smaller set of SKUs (only current and next season), and with no direct exposure to consumers. Once the basic setup was working smoothly and stores were supplied as expected, the project team added the additional requirements and complexity to execute online orders with pack stations and parcel shipments.

Executing the project, we used the Westernacher Q-Methodology which combines waterfall and agile methodology elements. Our methodology allowed us to quickly develop an understanding of the current situation (in three weeks). This was followed by intense workshops to establish a solution design document (SDD), fit-gap analysis, detailed execution plan, and final cost estimate. At the end of this four-week design phase, we were ready for development.

During development, we used an agile sprint approach which allowed us to show progress every four weeks. All the configuration and developments were assigned to one or two sprints. Every sprint started with creating detailed functional specifications documents (FSDs) based on the SDD. The customer reviewed the FSDs, and any questions were resolved in short workshops. After sign-off, we developed/configured the functional area or WRICEF item over two weeks (more for complex items). At the end of the sprint, we showed the results and gained acceptance from H&M IT and business for the finished WRICEF item.

Towards the end of the development, we started deployment activities, first with system integration testing, followed by user acceptance testing, performance testing, cutover, and final readiness testing.

Share this story